Chapter 5

Product 3D Modeling

3D modeling is the backbone of every CGI workflow. It covers all types of product rendering, animation, configurators, AR, and VR. No matter how advanced the final result looks, everything starts with a clean, accurate, well-optimized 3D model. If the model is incorrect, even the most well-adjusted lighting, materials, or animation will fail to look realistic.

A professional 3D model can be built from almost any input: photographs, CAD drawings, technical blueprints, video references, 360° walkarounds, or even 3D scans. What matters is translating these sources into geometry that meets the needs of rendering or real-time engines.

Just as importantly, models for photorealistic rendering and models for real-time interaction (AR/VR/web) are two very different categories.

- Rendering models prioritize micro-details and realism

- Real-time models prioritize polygon efficiency and speed

This guide explains all major modeling types, categories, complexity levels, reference requirements, outputs, software, and the complete workflow used at CGIFurniture.

Types of 3D Modeling

Below are the essential modeling types used in product visualization, along with examples, applications, and key benefits.

Low-poly Modeling

Examples:

- Simple chairs for configurators. These are clean, lightweight models, so people can swap out colors, materials, or finishes in seconds, without any lag.

- Basic light fixtures. The designs stay straightforward, focusing on good shape and proportions. They’re easy to render fast, and you can drop them into all sorts of scenes without a hassle.

- Accessories like baskets, trays, and minimalistic décor. Little touches like these make scenes feel real, but the geometry stays simple, so the files don’t get heavy.

Where it’s used:

- AR apps. These models are built for speed, so they run smoothly on phones and land right where you want them in the real world.

- Web configurators. Low-poly assets mean faster load times and a snappy, interactive experience.

- 360° interactive product viewers. Because the models are lightweight, users can spin things around and check them out from every angle.

- Mobile experiences. Smaller file sizes keep everything quick and easy on phones and tablets, and they help save battery too.

- Real-time engines (Unreal, Unity). Perfect for places where you need things to look good and move fast, with no slowdowns.

Key benefits:

- Fast loading and smooth browser performance. Users don’t have to wait, which improves engagement and reduces drop-off.

- Minimal polygon count. Keeps files lightweight while still preserving the overall shape and readability of the product.

- Ideal for animation and motion in real time. Models move smoothly and respond instantly to user input.

- Easy to scale for large catalogs. Makes it practical to manage and display hundreds or thousands of products consistently.

High-poly Modeling

Examples:

- Sofas with stitched seams. You can spot every detail here: the stitching, the folds, the depth of the padding. Even when you zoom in, nothing gets lost.

- Premium armchairs with quilting. These use layered fabrics and intricate patterns. To keep the shapes clean and the cushions looking soft, you need careful subdivision.

- Metal structures with chamfers and micro-details. Edges are beveled just right, and you’ll notice tiny imperfections on the surface. This stops the model from looking too sharp or fake.

Where it’s used:

- Photorealistic rendering (like with V-Ray or Corona). High-poly models really shine here because advanced lighting and materials bring out every detail.

- Product feature shots. Perfect for hero images where you want to show off the materials and craftsmanship up close.

- Advertising and lifestyle imagery. Great for scenes where the product needs to look premium, touchable, and real.

- Close-up shots. Even when the camera gets right in there, the geometry holds up. No weird edges or broken details.

Key benefits:

- Maximum realism. You get a look that feels just like the real thing.

- Shows off every detail. Fabric folds, stitching, beveled edges, dents, smooth curves—everything that makes a product feel high-quality.

- Supports micro-displacement and subdivision. Artists can add tiny surface detail without having to model every bump by hand.

CAD-based Modeling

Examples:

- Hardware and fittings. Things like hinges, brackets, fasteners, and connectors. They need to be spot-on with their dimensions.

- Technical components. Mechanical parts and assemblies where you can’t just simplify the shapes; accuracy rules here.

- Faucets, mixers, appliances. Products that hide a lot of complexity inside. They’re usually built straight from engineering drawings, so every millimeter counts.

- Industrial parts with tight tolerances. Pieces designed to snap together or line up perfectly during manufacturing.

Where it’s used:

- Exploded-view diagrams. These break down objects to show exactly how everything fits and works together.

- Technical presentations. Great for showing stakeholders how something is built or how it goes together, right down to the smallest part.

- Manufacturing visualization. It helps teams catch design problems before the real thing gets made, which saves time and money.

- Preparing for rendering. CAD models often need tweaking or conversion so they’re ready for photorealistic images.

Key benefits:

- High accuracy. You keep the original measurements and proportions from the CAD file, no guesswork.

- Perfect engineering geometry. Smooth surfaces, sharp curves, and precise angles all stay intact.

- Original dimensions stay true. This matters for validating designs, planning production, and keeping everything at the right scale in your visuals.

3D Retopology

Examples:

- Turning dense CAD models into clean versions. We take heavy engineering files and break them down into optimized meshes, but the shape and proportions stay true to the original.

- Getting 3D scans ready for rendering. Raw scan data gets cleaned up, holes get patched, and we rebuild the topology so the model actually works for visualization.

- Rebuilding models for AR or animation. Detailed assets get reworked into lighter versions that move smoothly and perform well in interactive environments.

Where it’s used:

- Real-time engines. Optimized topology keeps Unreal Engine, Unity, and other platforms running smoothly.

- AR/VR. Crucial for interactive experiences where you need fast loading and low latency.

- Product animations. Clean meshes mean smoother deformations and motion that’s easy to predict.

- Web configurators. Lets you show off complex products in a browser without bogging down performance.

Key benefits:

- Mid-poly models that work for real-time. Enough detail to look sharp, but not so much that it slows things down.

- Smoother surface flow. Clean topology means better shading and visuals that hold up under close inspection.

- Way smaller file sizes. Assets load faster and are easier to manage.

- Cleaner UVs and simpler texturing. Well-organized meshes make the texturing process smoother and cut down on weird visual glitches.

Model Categories

Each product type has its own nuances and technical requirements.

Furniture (Hard-Surface)

Examples: tables, cabinets, metal frames.

- Chamfered edges. Instead of leaving them razor-sharp, I bevel them a bit. That way, the model picks up light in a more natural way and looks way more convincing in renders.

- Clean geometry and sharp angles. Good topology and spot-on angles make the furniture feel sturdy and well-made, no matter how you look at it.

- Realistic wood and metal. I set up materials so wood grain, metal textures, and all those tiny imperfections react to light and aging just like the real thing.

Upholstered Furniture

Examples: sofas, poufs, armchairs.

- Cloth simulation makes fabric move and drape the way real material does. It reacts to gravity, stretches under tension, bunches up around corners—so it never looks stiff or fake.

- Cushion deformation matters too. Seats and pillows actually compress and sink where you’d expect, so the furniture looks soft and inviting, not like a hard prop.

- Wrinkles, folds, even the seams. These details show up right where they should. Up close, you see stitching and creases just like you would in real life, which adds depth and makes the whole scene feel more believable.

Lighting

Examples: pendants, floor lamps, sconces.

- Transparent and translucent materials. Glass, plastic, and diffusers let light pass through and spread out in a believable way, so the lighting never looks flat or too dark.

- Internal lamp structure. Bulbs, filaments, LED pieces, and the inside of each fixture are carefully modeled and shaded. Even when the light’s on, everything looks right.

- Correct refraction. Light bends through glass and clear parts just like it should in real life. Reflections, highlights, and that soft glow all show up naturally, even in close-up shots.

Décor & Accessories

Examples: vases, bowls, organic shapes.

- Complex curves. Smooth, flowing shapes get a lot of attention. They're modeled with care, so you don’t see weird shadows or lose that elegant outline, no matter where you look from.

- Glass and ceramics. These materials need special tweaking. You want just the right amount of reflection, a bit of translucency, and the sense of thickness. That’s what makes them look real and high-end.

- Imperfections for realism. Perfect isn’t the goal. Little flaws, uneven surfaces, tiny dents—these details make objects feel like someone actually made them by hand, not just churned out by a machine.

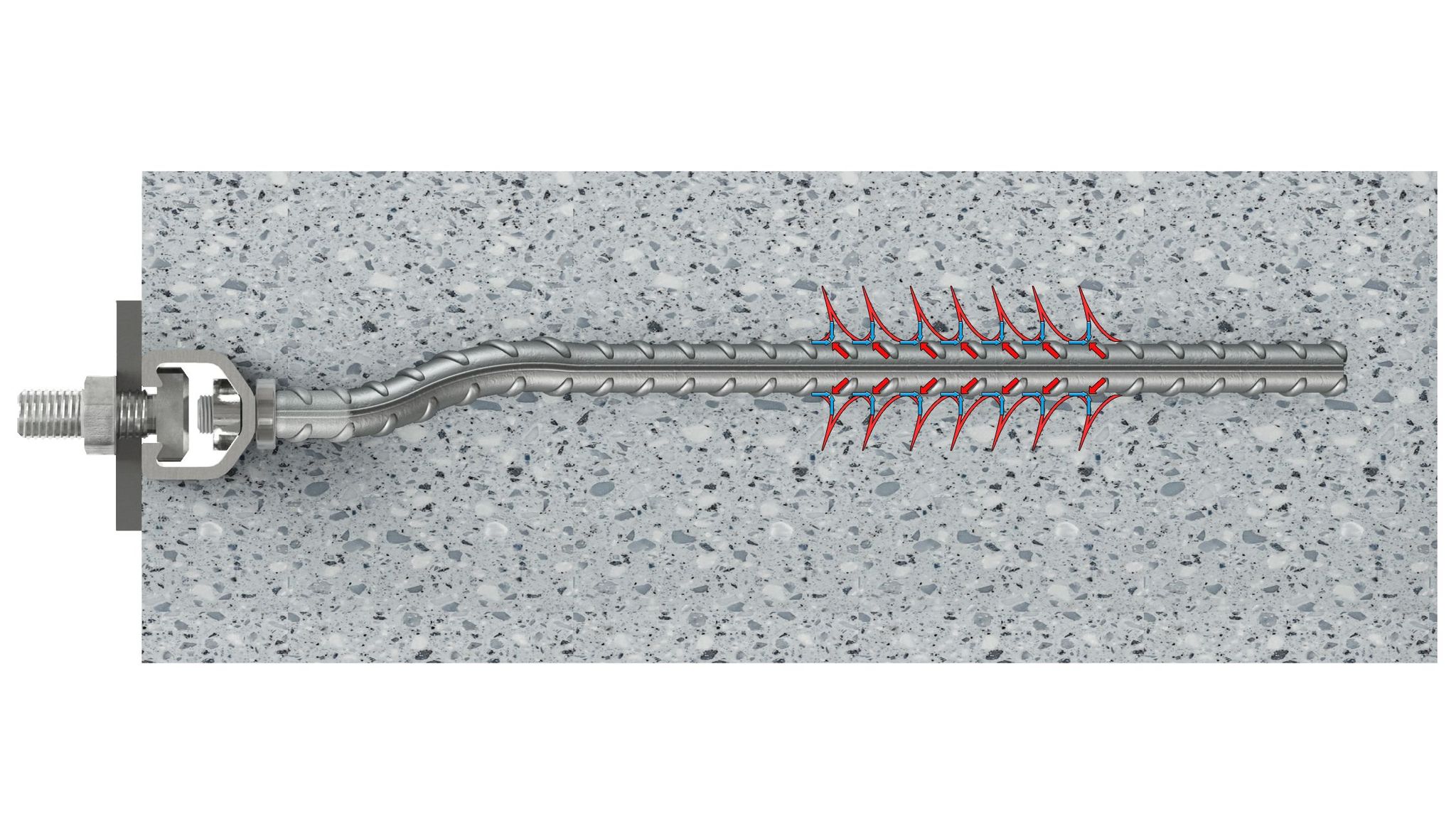

Technical / Industrial Items

Examples: fasteners, connectors, fittings.

- Engineering geometry means you stick to technical shapes and exact measurements, so every part fits together the way it should.

- High precision matters here. You keep everything within tight tolerances and nail the exact dimensions. That’s what makes technical visuals and manufacturing projects actually work.

- The small stuff counts, too — screws, joints, connectors, little grooves. You model these carefully because they’re the details that make everything function and feel real.

Outdoor Furniture

Examples: wicker items, metal frames, stone tops.

- Natural material variation. Surfaces show little shifts in color, texture, and roughness, just like real materials do when they’ve been out in the elements for a while.

- Non-perfect shapes. You’ll notice some warping, uneven edges, and those small, organic quirks that keep things from looking too fake.

- Weathering effects. Marks from sun, moisture, dirt, and everyday wear make these models feel like they actually belong outside, not just in some digital showroom.

Appliances

Examples: kettles, microwaves, ovens.

- Plastic and metal show exactly where they meet. Get the seams right, nail the reflections, and don’t forget about the feel of each texture.

- LED indicators make them shine like the real thing. The light should glow naturally, spill onto nearby surfaces, and look transparent where it should.

- Glossy surfaces and tight tolerances smooth finishes, sharp reflections, crisp edges. These little details really sell the idea of top-notch manufacturing.

Levels of Modeling Complexity

Below is a clear breakdown of the four main levels of furniture 3D modeling, based on CGIFurniture’s internal standards. Understanding these categories will help you identify the right model type for your product and plan your CGI budget more accurately.

1. Simple Models

What they are: Simple models feature minimal geometry and very few details. They are built from basic shapes such as cubes, spheres, cylinders, and work perfectly for straightforward furniture items such as basic chairs, tables, benches, or simple shelving.

Characteristics:

- No seams, stitches, or fittings

- No complex texturing

- Often created from ready-made geometry and standard texture maps

- Fastest and easiest to produce

- Typical production time: ~1 working day

- Price range: ~$40–$60

- When to choose this level: For minimalist products with clean geometry and no ornamental elements. Ideal for quick prototyping or basic catalog imagery.

2. Medium Complexity Models

What they are: Medium-level models include furniture with slightly more nuanced geometry — still fairly simple, but featuring more components and visible details.

Examples: Sideboards, bedside tables, TV consoles, chests of drawers, and similar cabinet pieces.

Characteristics:

- Moderate amount of decorative elements

- Simple fittings

- Common and uncomplicated textures

- Suitable for minimalistic or modern designs

- Typical production time: ~1 working day

- Price range: ~$80–$120

- When to choose this level: For furniture with clean lines but a bit more structural complexity. Perfect for most catalog-ready models.

3. Complex Models

What they are: This tier covers furniture that requires intricate geometry, rich textures, and precise detailing.

Examples: Chesterfield sofas, upholstered armchairs, refined cabinetry, or furniture made of premium materials.

Characteristics:

- Detailed stitching, quilting, and fittings

- Challenging textures (leather, silk, unique woods, stone patterns)

- May require retopology in 3ds Max to optimize geometry for smooth performance

- Suitable for real-time rendering, AR/VR, configurators, and 360° viewers (if requested)

- Typical production time: ~2 working days

- Price range: ~$140–$200 When to choose this level: When the product has elaborate detailing or when the 3D model needs to be optimized for interactive digital experiences.

4. Highly Complex Models

What they are: The top tier is used for furniture sets, multi-element compositions, or designs with extreme levels of sophistication.

Examples: Intricate furniture collections, items with carving, weaving, ornate materials, or many small components.

Characteristics:

- Large number of individual parts

- Extensive custom texturing and material creation

- Often requires retopology

- Each element is built with a fully customized approach

- Most time-consuming and detail-heavy modeling process

- Typical production time: ~2 working days (sometimes more, depending on set size)

- Price range: ~$220–$400

- When to choose this level: For luxury furniture brands, high-end marketing, or any product where visual realism and material accuracy are critical.

Factors Affecting Complexity

- Availability of CAD files or dimensions — the more accurate the references, the faster the workflow.

- Reference gaps — missing angles or low-quality photos increase complexity.

- Rigging requirements — hinges, openings, sliding parts, mechanisms.

- Material complexity — intricate textures, fabrics, patterns.

Reference Requirements

To create an accurate model, ideal references include:

- 360° video walkarounds

- Exact dimensions (height, width, depth)

- Close-ups of materials and details

- Finish options (colorways, hardware variations)

- Technical drawings or CAD if available

Accurate data reduces revisions and ensures scale precision.

Output

CGIFurniture provides models suitable for all pipelines:

High-poly (V-Ray / Corona)

High-poly models are used for photorealistic rendering in engines like V-Ray and Corona. They allow for maximum detail, including fine geometry, displacement, and subtle surface imperfections that are essential for close-up product visuals.

Mid-poly (Unreal / Unity)

Mid-poly models are balanced for real-time use in platforms such as Unreal Engine and Unity. They retain enough detail for configurators and animations while staying optimized for smooth performance.

Low-poly (AR / GLB / USDZ)

Low-poly models are designed for AR experiences and formats like GLB or USDZ. They are optimized for mobile and web environments, ensuring quick loading times and fluid interaction without sacrificing clarity.

UV Mapping

UV mapping is required when realistic materials are involved. Proper unwrapping ensures textures are applied correctly and is essential for any PBR-based texturing workflow.

STEM-ready geometry

STEM-ready geometry refers to models that are precise enough for manufacturing and technical visualization. These models feature clean topology, accurate dimensions, and consistent structure suitable for engineering-related use cases.

How a 3D Model Is Made

Let’s look at the 3D modeling workflow based on CGIFurniture’s pipeline.

Step 1: Studying the Assignment

This stage involves analyzing all available references, such as photographs, CAD files, videos, or scans, to fully understand the object. Any missing or unclear references are identified early on to avoid issues later in the process. At the same time, the team defines the model’s complexity and final output requirements, while also reviewing materials and color options to ensure everything aligns with the project goals.

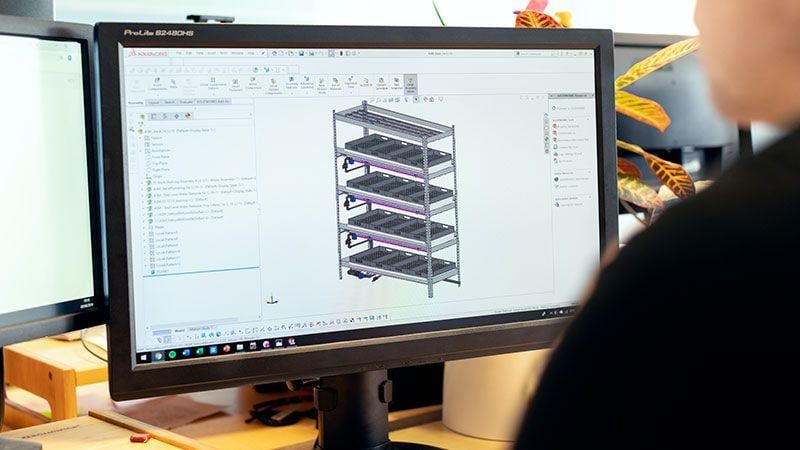

Step 2: Building Geometry

At this step, artists create the base shapes using either a high-poly or low-poly approach, depending on the project’s goals. They carefully ensure correct proportions based on the provided dimensions, then produce a gray (clay) model for early review and validation. Once the core form is approved, secondary and tertiary details are added to refine the model and prepare it for the next stages.

Step 3: Applying Textures and Materials

At this stage, artists apply materials using a PBR workflow, working with albedo, roughness, normal, and displacement maps to achieve realistic results. Fabrics, metals, wood, and plastics are carefully matched to references, and texture samples are reviewed and adjusted until they accurately reflect the intended look and finish.

Step 4: Rendering the Model on White Background

Next, test renders are created to verify the geometry and overall build of the model. Lighting is adjusted specifically to reveal any imperfections or inconsistencies, while scale and proportions are carefully reviewed using Silo 3D visualization to ensure everything looks accurate and realistic.

Step 5: Post-production

At this stage, any remaining artifacts are fixed and colors are corrected to achieve a clean, realistic look. The model then goes through a final scale verification to ensure accuracy, after which all assets are prepared and exported as the final deliverables.

Software for 3D Modeling

Different tools are used for different tasks and object types.

A. Hard-Surface / Product Modeling

3ds Max

Industry standard for product visualization.

Blender

Versatile: modeling + retopology + unwrapping.

Fusion 360

Great for mechanical and engineered shapes.

SolidWorks / Rhino

Used for CAD and highly accurate industrial forms.

B. Organic and Fabric Modeling

ZBrush

Best for sculpting and complex decorative shapes.

Marvelous Designer

Realistic cloth and upholstery simulation.

Houdini

Procedural modeling; ideal for complex forms and fabric logic.

C. Models for Production / 3D Printing

• SolidWorks • Onshape • Inventor • CATIA Used when exact dimensions and NURBS geometry are required.

D. Real-Time, AR, Low-Poly Pipelines

• Blender • 3ds Max retopology tools • Instant Meshes • Simplygon Real-time models require polygon optimization, clean UVs, and lightweight topology.

Why software choice matters

- Different tools for different geometry Hard-surface modeling and organic modeling follow completely different workflows. Software choice determines how accurately you can build sharp edges, chamfers, and mechanical parts versus soft forms, fabrics, and natural deformations.

- CAD models require visualization adaptation Engineering CAD files are precise but heavy and unsuitable for rendering out of the box. The right software allows proper retopology, cleanup, and optimization so CAD geometry can be used for CGI without shading or performance issues.

- Topology affects lighting and realism Clean, well-structured topology is essential for correct lighting, reflections, and shadows. Poor geometry leads to visual artifacts, even with high-quality textures and render engines.

- Output type defines the pipeline Models created for static renders, animations, AR, or real-time configurators all have different technical requirements. Choosing the right software ensures the model balances detail, performance, and compatibility for its final use.

Conclusion

When brands invest in professional 3D modeling, they speed things up, cut production costs, and stay flexible. You can swap out designs, materials, or colors without going through the hassle of reshooting photos or making new prototypes every time. Plus, when the models look real and the details are spot on, customers get a much clearer idea of what they’re buying. That kind of transparency goes a long way toward building trust before anyone even clicks “buy.”

With e-commerce and digital marketing on the rise, 3D product models aren’t just one-off visuals anymore. They turn into valuable digital assets that stick around for the long haul. If you nail the details, keep the models clean, and know what you want out of them, these assets carry your product from the first concept sketch all the way through engineering, sales, marketing, and whatever comes next.

Get the Commercial CGI & Product Rendering Guide for Marketing Directors

Everything you need to scale product content with CGI.

Get expert insights, real project examples, and strategies with proven ROI.

Fill out the form to receive the guide directly in your inbox.