In today’s world of high-tech advancements, the furniture industry has seen a paradigm shift. A new technology called 3D printing has opened up many new possibilities in the world of product development.

Product 3D printing is a technology that has been around for several years. It was first used to produce prototypes of products and parts, but now it’s growing in popularity as an alternative method for creating and producing finished products. Designers, manufacturers, retailers, and their businesses in the furniture industry benefit greatly from 3D modeling and printing technologies and can save money in the long run.

In this article, our 3D modeling company will discuss 5 areas where 3D printing of furniture models allows you to develop and improve your products to an innumerable extent.

Let’s dive into it!

What is 3D Printing of Furniture Models ?

Product development is the most critical stage of the product life cycle. It’s what gives direction to your company’s growth and dictates how well you meet customer expectations.

But, usually, it is a long, resource-intense process, because it involves idea generation and testing, design, development, prototyping, manufacturing, and logistics. And 3D printing is here to revolutionize the way furniture is designed and manufactured.

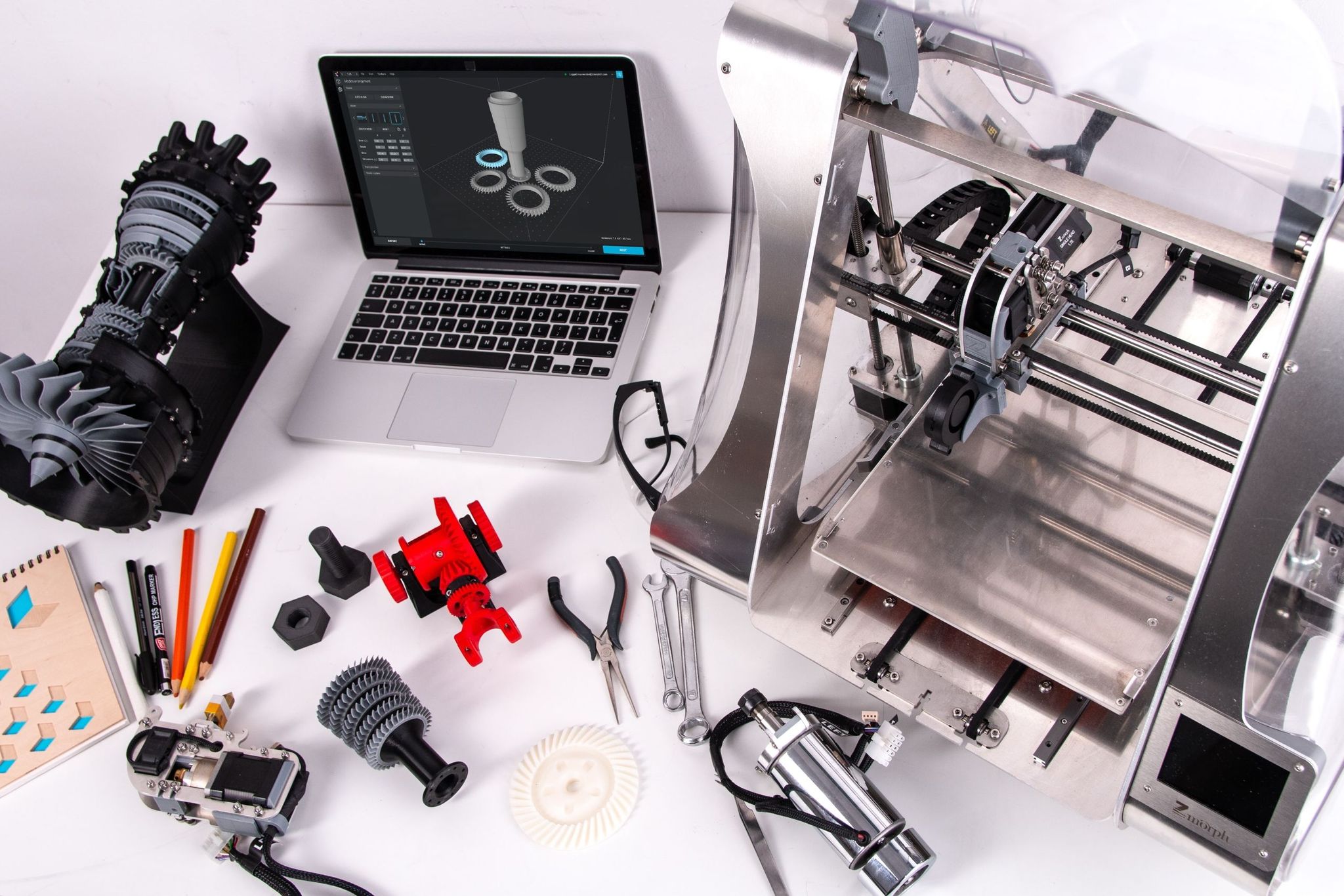

In 3D printing of furniture models , a digital model of the product is printed using technologies like SLA , SLS , FDM, and Polyjet .

Why Choose 3D Printing of Furniture Models?

Product 3D printing helps furniture designers speed up the development process. It became possible thanks to the flexibility it provides while keeping costs low compared to traditional tooling methods (like CNC machining or plastic injection molding).

While it can be used to print a wide range of materials, including rubber, plastic, metal and even living tissue, 3D printing may be best suited for manufacturing furniture parts or components that are relatively small and made out of a non-mechanical material. It’s also possible to combine 3D-printed parts with traditional pieces such as wood or glass.

Below, we give you the lowdown on how furniture manufacturers and business owners can adopt 3D printing of furniture models to develop better products.

1. Speeds Up The Design and Manufacturing Process

Furniture 3D printing is one of the most exciting technologies in the field of product development. It has the power to solve complex geometrical problems and improve product quality. It provides design freedom and makes extraordinary designs possible.

The ability to visualize an object and create variations on it makes design iterations faster, easier, and cheaper than ever before. This means that designers no longer have to wait for weeks or months before they find out if their designs are viable or not. Instead, they can make changes on the fly and see results immediately.

A 3D printing of furniture models allows companies to produce customized designs for each customer without having to spend much time or money on tooling or material costs. This makes it an ideal choice for businesses that want to offer personalized products at lower costs than ever before!

2. Eliminates Expenditures During the Prototyping Phase

Prototyping based on 3D printing is key in designing a new product. A furniture model is used to iterate on product design and manufacturing processes before costly production runs. To create a prototype, first, you need to create a product 3D model for printing. After that, a 3D printer can produce a model of the product in a matter of hours. Yes, 3D printing has revolutionized the prototyping process, but it doesn’t just stop at model making.

A lot of CAD modeling software takes care of these details for you by calculating how much material will be needed for each component of your design based on the product dimensions. This means that you can accurately predict the cost of your prototype before you even build it.

When manufacturing a large number of products, it’s important to have an accurate and realistic representation of the number of materials and other spending you’ll need. Printing 3D models ensures that manufacturers can plan their budgets and avoid unnecessary waste.

3. Tests The Product at the Early Stages of Development

Prototyping offers an opportunity to test your ideas before making any investment in expensive tools and molds required for production. Being able to test several iterations of your design allows you to continually improve it until it’s perfected. 3D-printed models of furniture are durable and impact-resistant, making them ideal for testing.

On top of that, 3D prototyping allows for real-time feedback and testing of a product at an early stage of development. 3D printing of furniture models helps designers review their geometries, ergonomics, and even aesthetics. This means that if there are any changes or adjustments that need to be made, they can easily be incorporated before the final product goes into production.

4. Ensures Effective Inventory Management

Your company needs to be able to produce parts regularly and economically to meet its needs. To do that, you need a sufficient inventory of production materials in the right quantities. A lack of good inventory management can lead to excess spending, lost revenue, and lower profits from late deliveries.

As we said above, 3D printing is also used to create spare parts or even replacements on demand. With a well-managed inventory, you can make sure that every part produced with your 3D printer is used when needed.

Make sure to keep track of how many of each type of part you’ve printed so far (and how many are in use), so that you know how many more should be printed before something else needs to go through the printer. This can save companies millions of dollars by ensuring that all their products are fully functional at all times.

5. Provides a More Precise Product Development Cycle

High-quality 3D printing of furniture models is an innovative and economical alternative for furniture prototyping and product development. The process allows designers to create complex shapes and designs that can be difficult to achieve with traditional manufacturing processes.

The technology also enables rapid design changes and allows for the optimization of details, which improves the aesthetics of a design while ensuring its function is optimized. By bringing in a digital approach to solve design challenges, 3D printing promises to be one of the game changers in the field of product development.

It’s not necessary to be familiar with CAD and 3D modeling software, which can be daunting and expensive. Rather, you can go check out our 3D modeling services that can help you turn your idea into reality for less time and cost than you might expect!

If you have some creative itch that needs scratching, such as making your own custom furniture or home decor products, here are some suggestions for preparing 3D modeling image references . Contact us now or book a demo to learn more about how you can take advantage of the latest technologies in digital design and product development!