The furniture manufacturing industry is no stranger to the ebb and flow of trends, which evolve in ways that can be challenging to anticipate, even with advanced analytics. With shifts in consumer preferences, advancements in technology, and changes in the market landscape, it’s clear that a new wave of trends is on the horizon. The surge in demand for furniture reflects notable shifts in consumer behavior and preferences. As individuals seek to invest in furniture, their expectations have evolved considerably. To stay competitive, furniture manufacturers must adapt their strategies to these changing trends. Here are 10 key trends compiled by our rendering studio that industry professionals can use to adapt their strategies and stay ahead of the curve.

#1. The Triumph of E-commerce In Every Business Field

E-commerce in the furniture industry has evolved significantly, with a shift towards personalized online stores catering to specific niches. Platforms like Joss & Main, Joybird, and Wayfair offer immersive 3D imaging and comprehensive price lists, enhancing the overall shopping experience. Despite the inability to physically inspect furniture, consumers are increasingly comfortable making online transactions. With e-commerce sales now constituting approximately 16.4 percent of global sales, this trend is both prevalent and enduring, driven by convenience and accessibility.

How does this affect the furniture manufacturing industry?

In 2023, global retail e-commerce sales reached an estimated 5.8 trillion U.S. dollars. Projections indicate a 39 percent growth in this figure over the coming years, with expectations to surpass eight trillion dollars by 2027. They are no longer an afterthought but rather a primary avenue for marketing and sustaining sales figures. For traditional furniture manufacturers, establishing a robust e-commerce platform is imperative to showcase their products effectively.

Furniture brands need to invest in their online stores to attract visitors and build a loyal customer base. For those already online, innovation is crucial, such as offering store pickup or virtual experience images for customers to visualize furniture in their space. Embracing these advancements enhances the online shopping experience and keeps brands competitive in the evolving market.

#2. The Rise In Demand Of Sustainable Furniture

According to a Hartman Group report, 84% of the population falls within the category of “World of Sustainability”. This trend demonstrates a growing consumer consciousness toward environmental sustainability, as individuals seek a balanced approach to their purchasing decisions. One manifestation of this shift is the increasing preference for sustainable furniture, crafted from recycled materials and eco-friendly woods like bamboo and acacia.

Reclaimed wood, sourced from old structures, is a popular and sustainable choice for furniture. Its durability and resilience, along with its unique history, add charm to each piece. Additionally, reclaimed wood furniture is affordable, providing quality craftsmanship at a lower cost than newly manufactured alternatives.

How does this affect the furniture manufacturing industry?

As buyers are shifting towards more eco-friendly furniture, retailers too must make it a point to adapt to this mindset. No matter how smart or attractive the furniture may be, it will not be popular if it is not made without keeping sustainability in mind. This is why many designers are paying personal attention to how they can source sustainable materials and fashion them into attractive furniture items.

Some brands have even made a name for themselves in this area. Existing retailers in the industry such as Crate & Barrel are already making their mark by making furniture frames that are Forest Stewardship Council-certified. Also present are a few other brands that are devoted to exclusively making sustainable furniture. This includes Room and Board, which manufactures its furniture with wood that is locally sourced and sustainable, and Pottery Barn, which extensively uses reclaimed wood for its products.

#3. The Essential Role of Social Media In Furniture Shopping

Social shopping has surged in popularity, offering personalized yet accessible shopping experiences across various platforms. Platforms like Facebook and Instagram have transformed into e-commerce hubs, enabling users to buy furniture directly from their feeds. Instagram’s “Checkout on Instagram” feature enhances the shopping process by enabling sharing and shopping without third-party apps.

Pinterest has emerged as a powerhouse in social shopping, especially favored by buyers. Its visual search feature uses machine learning to match pinned images with items in its library, providing direct links to furniture retailers’ websites. This saves buyers time spent on manual searches. Social media influencers also play a significant role in influencing consumer choices with their endorsements.

What does this mean for the furniture manufacturing industry?

For the furniture manufacturing industry, social media pages are no longer merely supplementary to websites or physical stores—they have become standalone shopping platforms. This paradigm shift underscores the necessity for furniture manufacturers to establish a robust social media presence. Even a basic social media strategy can kickstart a business’s social activities without straining budget or operations.

For those already active on social media, it’s crucial to elevate their approach to accommodate direct social media orders. High-quality images are paramount, with the potential to go a step further by incorporating realistic 3D product images. This immersive experience allows customers to visualize furniture as though it were physically present. Additionally, retailers should actively engage with key social media influencers in the industry to leverage their reach and promote products effectively.

#4. The Use Of CGI For Product Imagery

With more people browsing for their furniture online, they want to have the most authentic information possible. Simply having a well-written description and a list of specifications do not work here as customers need to understand what exactly it is that they are paying for. In the earlier days, high-quality product photography would serve this purpose but now furniture manufacturing industry professionals have been using CGI more and more.

Besides still life-like renders, CGI gives more engaging options such as AR and 360-view spins. This gives customers a sense of ownership and a deep level of personalized connection with the products they view — something that even the most high-quality photographs cannot achieve. While this is still a relatively new practice, it is gaining speed very fast, and will soon be at the forefront of product imagery.

What does this mean for the furniture manufacturing industry?

According to a report by the CXL institute, it takes customers an approximate time of .05 seconds to form their opinion on a website. Any furniture manufacturer in this position would want to attract and retain as many as they can. In an industry that is extremely visually oriented as furniture, the only practical way to do things is to use CGI instead of product photography. These images can be easily adjusted by 3D artists according to any concept, not to mention a 360-degree mode and 3D animation, which are even more dynamic than 2D images.

CGI services also cost less than traditional photography and can easily be integrated into websites and social media platforms, which makes marketing more standard. Manufacturers should make sure to have the images of their products showcased in a white-background mode and a lifestyle mode. The former highlights the product features, while the latter gives a preview of the furniture in a real setting.

#5. Changing Lifestyles And Its Demands

In the last few years, the percentage of renters has increased sharply. According to a Pew Research Center report, over 36.6% of breadwinners lived in rented homes as of 2016 — the highest percentage since 1965. There are several reasons for this change, most of which are related to the rise of millennials becoming the larger percentage of the active workforce. They have a new and different set of challenges compared to their previous generations, which includes (but is not limited to) the rise in home prices, student debts, and getting married at a later age.

More rentals mean a rise in demand for a very specific type of furniture — both from landlords and renters. While landlords are looking for cheaper furniture, renters are generally looking for furniture that is compact, lightweight, easy to handle and move, and lighter on the wallet. Many landlords and tenants are even open to the idea of renting manufactured furniture for larger amounts of time, as opposed to owning them.

How does this affect the furniture manufacturing industry?

To address the decline in traditional heavy furniture sales, manufacturers should diversify product lines to meet the needs of millennial renters, who prioritize functionality and affordability. Understanding the psychology of landlords and renters is crucial to effectively appealing to them.

One approach is to forge long-term partnerships with stakeholders in the real estate sector, such as housing complexes and furniture rental companies like Aaron’s Inc. and Rent-A-Center. This ensures a consistent demand for products while adapting to changing renter preferences.

Despite the initial investment in innovation and design, the potential for revenue growth and brand promotion is substantial. Manufacturers should seize this opportunity to expand their offerings and establish themselves as market leaders.

#6. Changing Demography of the Workforce

With more and more millennials and Gen Z members coming to the forefront of the population, it isn’t just lifestyle and housing choices that are experiencing a demographic shift. This is especially true when it comes to jobs in the furniture manufacturing industry. With those in the older generations retiring in large numbers, Millenials and Gen Zs are taking over the bulk of the manpower used in manufacturing companies.

Given their different lifestyle, they have a different set of skills and priorities and are not particularly wooed by the factors that appeal to older generations. For instance, the idea of owning their home before they are 30, or having a hefty pension plan carries a lesser appeal to them, as opposed to having a second master’s degree. Millennials and Gen Z employees place a high value on personal development, and they expect the furniture manufacturers they work for to align with their values and perspectives.

How does this affect the furniture manufacturing industry?

Even with the amount of automation and robotics present today, a factory is only as good as its workers. This makes investing in the workers a high priority for furniture manufacturers to survive. Businesses should start by accepting that these younger workers were brought up in a different world, and therefore have a different mindset.

Industry professionals must conduct market research and find out the wants and needs of younger vs. older workers, then devise a plan to balance their priorities with their goals. For instance, many younger workers are often pursuing courses on the side. Sponsoring them or even helping them out with such coursework as a reward can be a great way to appeal to them and have them continue working with dedication.

#7. Reducing A Looming Skills Gap

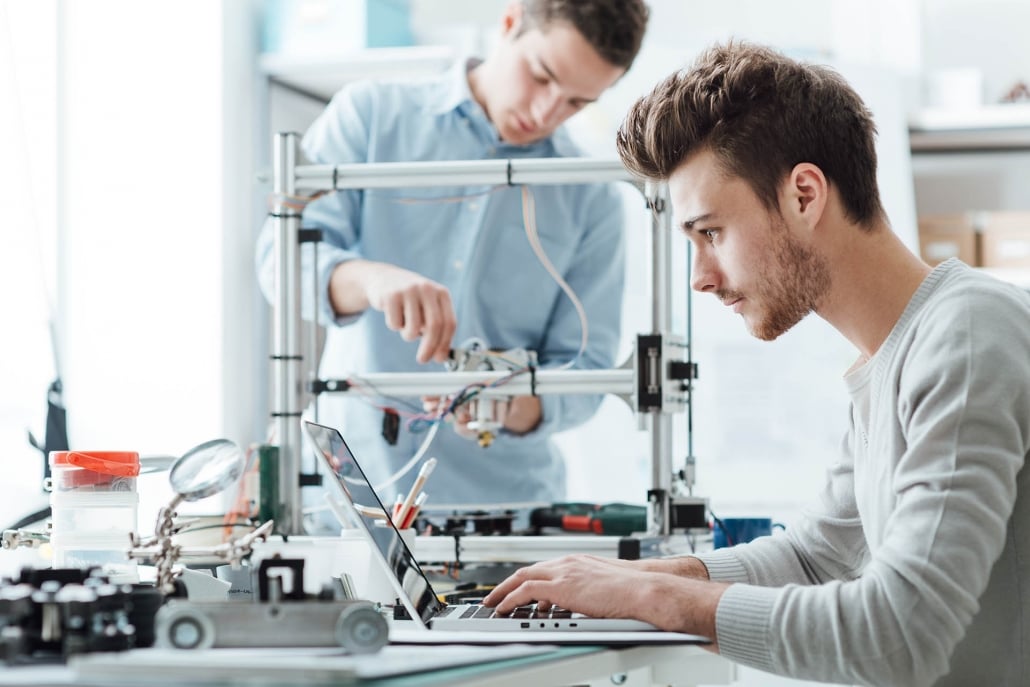

One of the biggest challenges that the furniture manufacturing industry is currently facing is a looming skills gap. While the technology and machinery involved in manufacturing furniture have advanced in leaps and bounds, the workforce to control and monitor them hasn’t quite gotten up to speed. Older workers usually lack the technical training and know-how of sophisticated manufacturing equipment such as 3D printers, CNC machines, and robotic systems. Most of them being close to retirement already, choose to retire rather than “take risks” with said complications.

Meanwhile, the younger workers do have the digital skills and the ability to understand such equipment but tend to lack a solid STEM background that could help them fully realize their potential in the industry and work to the best of their abilities. If allowed to be fostered, this skills gap will soon create a scenario where manufacturing units will have a severe dearth of skilled and able workers.

How does this affect the furniture manufacturing industry?

If seen with the correct perspective, this alleged “gap” for manufacturers is actually a great opportunity. No matter what the age group, education, when done right, enlightens people and brings them together. For instance, manufacturers can start specialized workplace courses for older workers that demonstrate how new machinery can contribute to lesser stress and work-related injuries. They would choose to learn rather than run away.

At the same time, furniture manufacturers can also create opportunities for the younger generations to learn industry-relevant STEM skills from the get-go by creating Makerspaces in schools, colleges, and universities. These are places where students (both children and adults) learn and work on a project on their own, and therefore, also double-up as great recruitment platforms to hire those with talent and potential.

#8. Manufacturing-As-A-Service (MaaS)

When it comes to actual sales of furniture, furniture manufacturers have traditionally relied on an indirect B2B model. This model works by having these manufacturers sell their products to distributors, who would then sell the products to customers. Now, however, this is slowly giving way to a model that is based on “Manufacturing as a Service (MaaS)”. Just as how SaaS works for software companies. MaaS helps furniture manufacturers create direct relations with the end customer.

For instance, there is a complex full of rental properties that require home furniture. In the earlier days, the landlord would have to buy from their local furniture store. Now, however, they have the option to contact the manufacturer directly, create a long-term partnership, and buy (or even rent) in bulk. This allows furniture makers to directly sell their capabilities (i.e. manufacturing) as a service (i.e. something that the customer directly pays them for).

What does this mean for the furniture manufacturing industry?

In today’s internet-powered, profit-driven world, entrepreneurs are always on the lookout for a business model that can maximize gains for both the producer and the consumer. MaaS helps uniquely fulfill this. By eliminating the retailer, the model helps manufacturers price their furniture at a rate that is higher than their B2B rates, but lower than what retailers would offer to customers.

This combined with the fact that manufacturers can fulfill bulk demands faster when they are contacted directly makes for a solid services-based model. This will motivate more and more customers to sign up to work directly with the manufacturing industry. MaaS is lucrative for sure — even the e-commerce giant Amazon has started its own line of furniture that is sold under its own, exclusive brand.

#9. The Rise Of Machine Learning and Robotics

Although the idea of automation has been around for a while, it has so far been there as a formality, or as one says “automation for automation’s sake.” With the success of machine learning and robotics, however, this trend is rapidly changing. The furniture manufacturing industry is increasingly using tools that are being created with the help of these technologies.

Consider robots as an example: with advancements in artificial intelligence, they have acquired unprecedented abilities like skill learning and visual recognition. This evolution enables them to execute a wide range of intricate tasks in significantly less time. The utilization of robots in collaborative efforts with humans, known as “co-bots,” is on the rise. In this setup, a human worker is paired with a robot, allowing for enhanced efficiency. While robots handle tasks such as data collection and programming, humans can concentrate on more creative endeavors.

What does this mean for the furniture manufacturing industry?

Putting aside conspiracy theories and science fiction, robotics, and machine learning stand as crucial technologies for manufacturers looking to sustainably grow their production. Leveraging these advancements empowers business owners to achieve significant enterprise goals, including faster decision-making, heightened rates of improvement and innovation, streamlined operations, and effective cost control.

As demands escalate and competition intensifies, relying solely on human labor becomes impractical. Conversely, fully automated factories are not yet feasible. Hence, manufacturing units must strategically integrate robots to enhance their production sustainably.

#10. Rise In The Need For Customised Products

In an age when the number of choices for a single product is endless, customers are spoilt for choice. A single iteration of a product, therefore, is never enough. People are always on the lookout for new and innovative customizations. These may come in the form of colors, materials, and even value-added features. If customers do not see much customization in a product, they tend to move on to other products and even other companies.

Bolia Furniture is one of the best examples of this trend in the furniture industry right now. While their catalog offerings are fairly limited, they have a wide range of customization offers. Every item on their website can be customized in a variety of options. This makes for multiple iterations of the same basic style, both in terms of the color and the material used. Being able to make these choices and order them gives customers a level of satisfaction like no other.

What does this mean for the furniture manufacturing industry?

Today, furniture manufacturers face heightened production complexity. Balancing customizations with budget constraints and operational efficiency is paramount. To prevent supply chain strain and operational overload, manufacturing units opt for rapid site assessments. Conducted by third-party contractors, these assessments compare a unit’s capabilities with demands and offer recommendations for optimization. Ultimately, the goal is to maintain smooth production systems amidst relentless customization demands.

In today’s fiercely competitive furniture manufacturing industry, innovation is key to success. Adapting manufacturing systems to incorporate key innovations is essential for efficiency and competitiveness. By embracing top trends and updating processes accordingly, industry professionals can pivot their businesses to thrive in the market.

Looking for top-notch visual materials to keep your business in line with the best furniture e-commerce trends? Contact us at CGIFurniture for high-quality product rendering services and get imagery that your customers simply cannot turn away from.

Leave a Reply

Want to join the discussion?Feel free to contribute!

The ideas about furniture making industry. It really shows that different industries could really affect the furniture industry. So, how does this really affect the furniture making industry ?

Nice explanation about furniture manufacturing industry.

This overview of the top 10 trends in furniture manufacturing provides key insights for industry professionals. But for people who are not experts, everything written above is innovation.